Ship Engine Basic Configuration

Ship Engine Basic Configuration

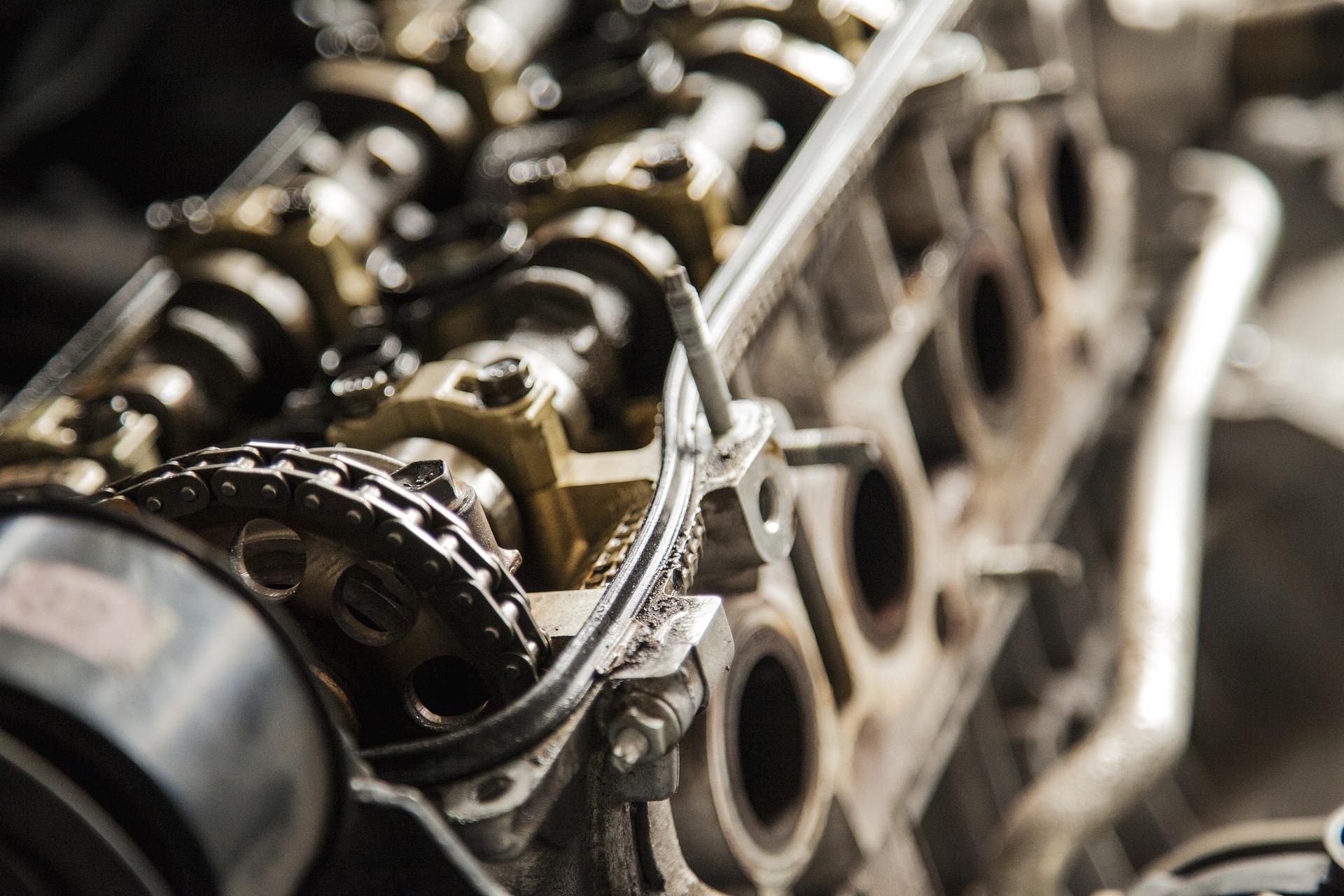

2019/04/10 - [자동차 & 선박 디젤 엔진 ] - INSTRUCTION MANUAL HEAVY DIESEL ENGINES!! INSTRUCTION MANUAL HEAVY DIESEL ENGINES!! Information sharing on diesel engines I am a Korean. Please understand even if I am not good at English. As I am interested in korea ship engines and korea car engines, I would like to share the inf.. ezexec2.tistory.com Ship Engine Basic Configuration The Diesel is designed as a ..

자동차 & 선박 디젤 엔진

2019. 4. 18. 15:27

공지사항

최근에 올라온 글

최근에 달린 댓글

- Total

- Today

- Yesterday

링크

TAG

- 선박부품

- 디젤엔진

- 조선단어

- 연금복권 당첨번호

- 배기

- 꿈풀이

- 꿈해몽

- 로또박사

- 엔진 정비

- 해양용어

- 해양플랜트

- 로또당첨번호

- 거버너

- bmw리콜

- 흡기

- 해양언어

- 인물꿈

- 로또1등당첨지역

- 해양단어

- 선박

- 해양조선

- 흡배기

- 조선용어

- 조선말

- 조선

- 선박용어

- 선박단어

- 오늘운세

- 의장

- 속도조절

| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| 27 | 28 | 29 | 30 |

글 보관함

반응형